Pet bottle and preform testing instruments

PET Bottle And Preform Testing Instruments:

Perfect Equipments is the fastest-growing brand for pet bottle testing Instruments and preform testing instruments

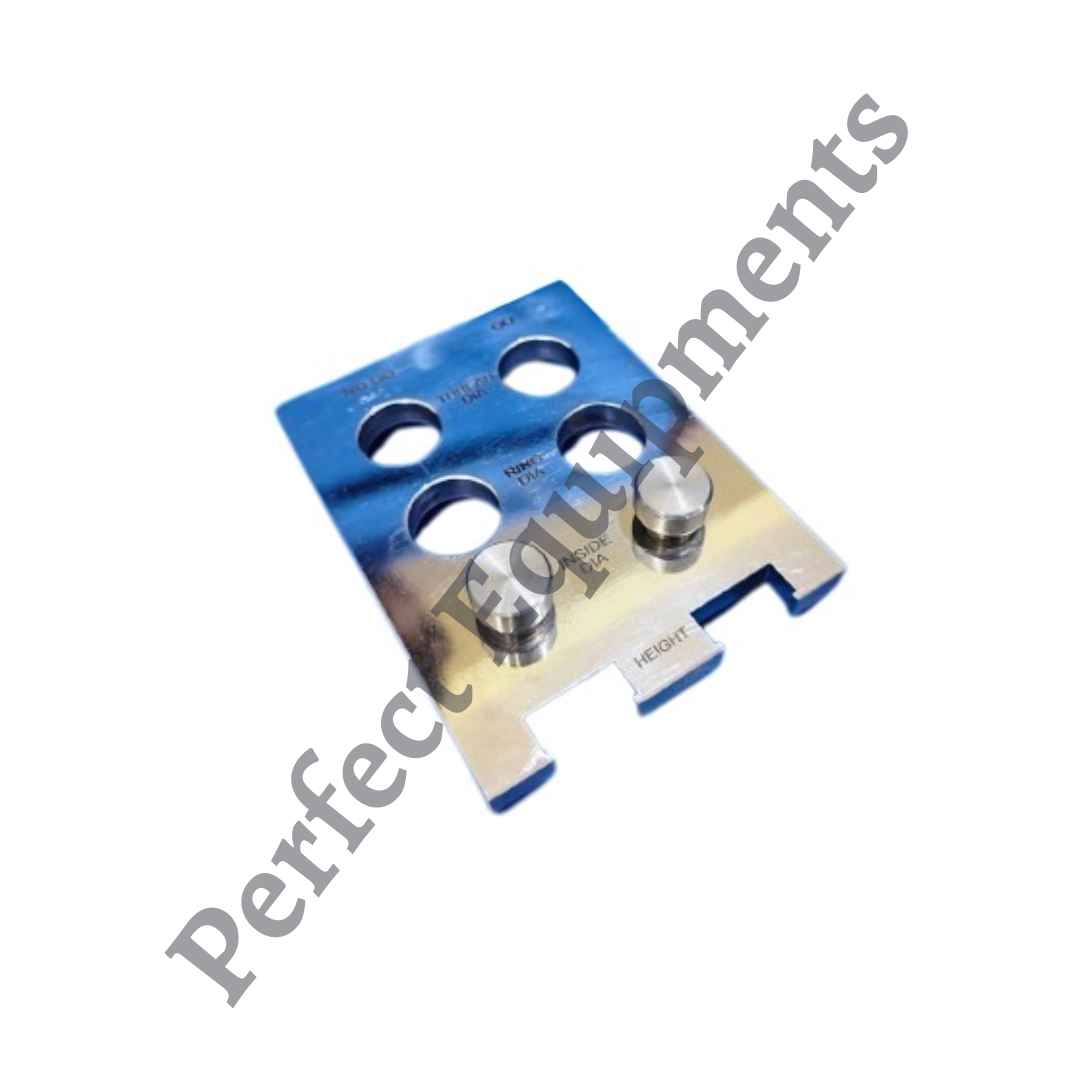

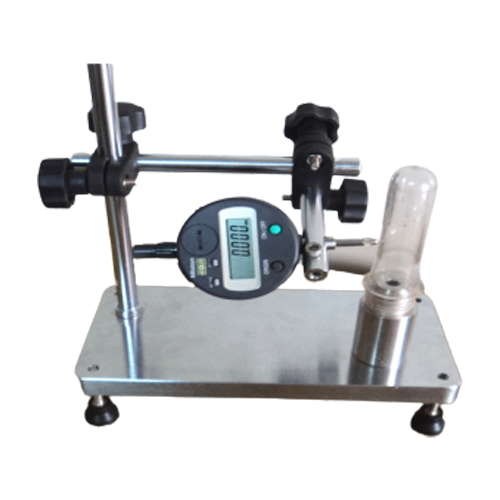

PET bottle and preform testing instruments are the premium devices which are put into use to assess the integrity of certain products such as PET bottles, containers, preforms, flexible PET packaging and the range is vast.

In numerous industries, such critical devices are widely used such as in beverage manufacturing, medicines, chemical industries etc.

Types of Content That Is Tested By PET Bottle And Preform Equipment:

Pet preform testing instruments are one of the most important tools you can use to help diagnose and treat orthopedic problems in your pet.

With this device within a hand’s grab, we are empowered to test a wide range of material, such as PET packaging items, like bottles, containers and many types of caps as well as PET preforms and this is for the sole purpose of quality analysis at crucial and early stage.

The basic objective of this device is to assess PET material that is used in many types of bottles of enclosed packaging systems.

Type Of Factors Or Properties That PET And Preform Machines Can Gauge:

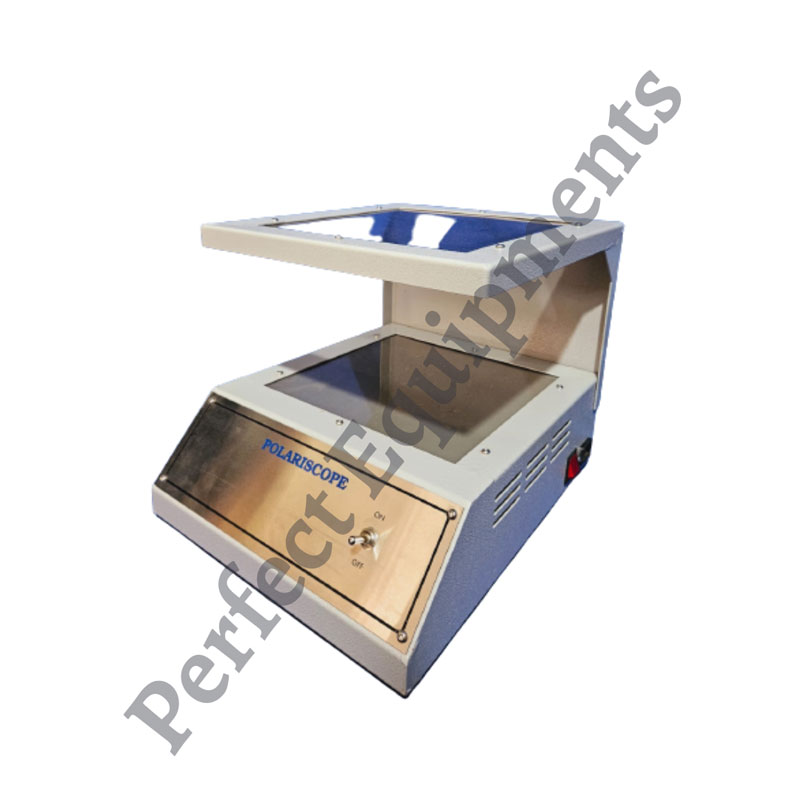

A handful of factors are put to test, such as the resistance to vertical pressure, stress and strain origin, carbonation assembly, impact of any push and shaking action, the torque force applied on the bottle cap, resilience to instant huge impact, impact from sudden drop, vacuum leaks, moisture absorbed, height of bottle filling, seal quality, thickness of inner and external wall, force and pressure dynamics, material transparency, perpendicularity and so many more.

What makes our manufacturing and devices so outstanding?

Clearly, we are a big name and command respect in our industry. When anyone thinks about PET bottles and preform testing instruments and also about ways to secure the soft drink PET bottle.

The testing devices that we manufacture are of high precision and numerous industries count on our world class manufacturing set-up and expertise and include our measuring devices in their manufacturing process.

Salient features of our PET bottle and preform testing device-manufacturing are as follows:

● A huge and sprawling manufacturing facility enhanced with state of art machinery and automation which result in making top class devices.

● Highly skilled workforce.

● Each unit is quality tested for precision, promise and durability.

● Customer care unit to resolve any issues while full warranty is extended on each item,

● Materials of best grade are utilized when we set out to manufacture and fabricate our testing devices.

● Our items always meet the set standards of DIN, ASTM, ISO and BIS.

● We have won hearts in our country and abroad as many Indian and foreign companies have been our regular customers.

● We guarantee quality performance and replacement is done when any error arises, though such cases are scanty.

With an enormous wisdom of over two decades into manufacturing and having gone through many ups and downs, we have emerged as the industry leader in the field of PET bottle and preform testing equipments.

Please go through the customer reviews and user feedbacks and how much successful we have been in catering to our customers when they seek absolute PET bottles and preform testing equipment.

Types of Content That Is Tested By PET Preform Testing Instruments:

PET Preform Testing Instruments are essential for the quality control and assurance of PET (Polyethylene Terephthalate) preforms used for manufacturing PET bottles, jars, and other containers. The instruments are designed to perform various types of tests to ensure the preforms' physical, mechanical, and thermal properties meet the industry standards and customer requirements.

PET Preform Testing Instruments play a vital role in ensuring the quality and consistency of PET preforms used for manufacturing PET bottles, jars, and other containers. These instruments perform various types of tests to evaluate the preforms' physical, mechanical, and thermal properties and ensure they meet the industry standards and customer requirements. By using PET Preform Testing Instruments, manufacturers can identify and address any quality issues before they become a problem, ensuring their products meet the highest standards of quality and safety.

Types of Content That Is Tested By PET Bottle Testing Instruments:

PET Bottle Testing Instruments are used to evaluate the quality and consistency of PET (Polyethylene Terephthalate) bottles, which are widely used in the packaging industry due to their durability, lightweight, and transparency. These instruments perform various types of tests to ensure the bottles' physical, mechanical, and thermal properties meet the industry standards and customer requirements.

One of the most important tests for PET bottles is the Burst Test. It measures the amount of pressure the bottle can withstand before it ruptures. A Burst Tester is used to perform this test, and it applies pressure to the bottle until it bursts. The test ensures the bottle can withstand the pressure exerted by the liquid inside and any external stresses and strains that may occur during handling, transportation, and storage.